ELECTROMECHANICAL MAINTENANCE

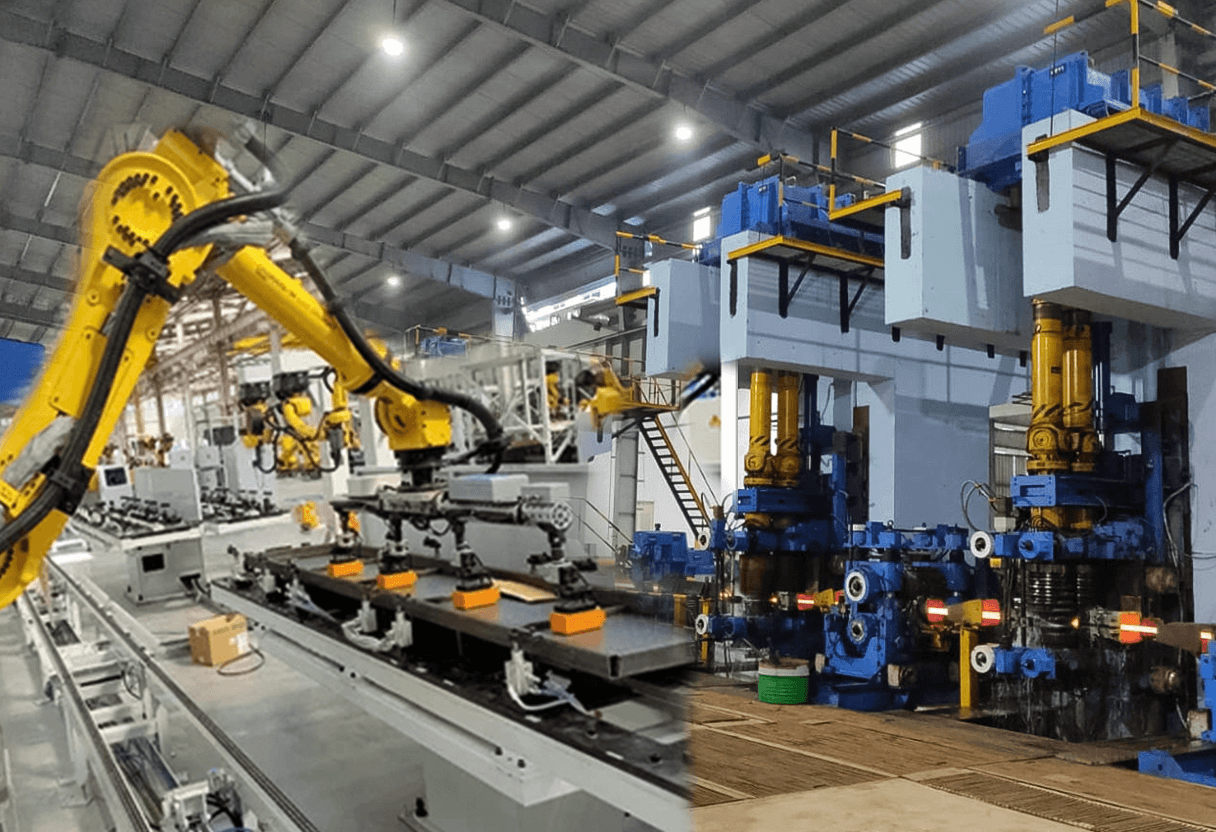

Electromechanical maintenance represents one of the most complex operational disciplines, combining mechanical power transmission with electrical and automation control intelligence. This dual-layer reliability is crucial in steel mills, where rolling lines endure thermal and mechanical stress, and in airports, where HVAC, baggage automation, passenger mobility systems and pumping equipment must run continuously without failure.

The objective is to ensure complete synchronization between motion systems, power systems and control systems — protecting performance, safety and operational efficiency across every electromechanical component.

In steel production, any failure in hydraulic drives, conveyor actuators or cooling systems can completely halt casting and trigger major losses. Real-time monitoring, vibration analytics, thermal tracking, motion sequencing audits and power-logic diagnostics detect degradation in bearings, solenoid valves, servo motors, electronic boards, hydraulic boosters and multi-axis automation assemblies — ensuring stable torque, balanced fluid power and smooth actuator/sensor communication.

At airports, electromechanical reliability directly impacts passenger experience and safety. HVAC networks, sorting systems, elevators, escalators, baggage conveyors, jet bridges and pumping equipment depend on synchronized electro-mechanical performance. Through load-feedback systems, programmable logic monitoring and actuator-response analytics, this discipline ensures 24/7 system uptime where downtime is not an option.

HVAC & Cooling Systems Electromechanical Support

“Precision Air-Cycle Optimization for Thermal-Critical Operations”Covers chillers, AHUs, FCUs, cooling towers, VFD blowers, thermal pumps, dampers and electromechanical control loops. Flow calibration, valve-stroke measurement, vibration correction and PID tuning ensure uniform cooling and minimum power consumption — stabilizing server clusters and furnace zones in steel plants and airport terminals.

Conveyor & Automation System Electromechanical Support

“Seamless Mechanical-Motion and Electronic-Control Synchronization”Targets steel rolling lines and airport baggage systems with chain tensioning, drive rollers, pneumatic/servo actuators, encoder signal validation, PLC commands and SCADA feedback. Torque mapping and motion waveform correction prevent vibration resonance, timing delays and bottleneck jam conditions — ensuring uninterrupted throughput.

Pumping & Hydraulic System Electromechanical Support

“High-Pressure Performance with Continuous Hydraulic Output Stability”Conducts seal integrity checks, contamination testing, pressure valve recalibration, pump–motor alignment, servo-valve response audits and accumulator performance monitoring. Circuit optimization prevents cavitation and thermal stress, maintaining uninterrupted hydraulic output for casting lines and runway operations.

Elevator & Escalator Electromechanical Support

“Secure and Smooth Vertical Mobility with Fail-Safe Controls”Manages traction drives, electrical control panels, safety sensors, braking assemblies, encoder stability and inverter tuning. Load-test analysis ensures zero breakdown risk during heavy passenger movement, terminal peak hours or industrial shifts.